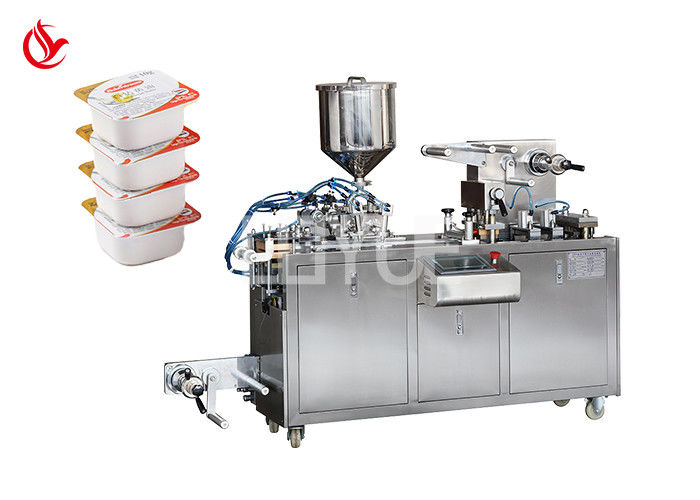

Butter Box Blister Pack Sealing Machine Fully Automatic 220V 50Hz

Product Details:

| Place of Origin: | Shenzhen China |

| Brand Name: | LEIYUE |

| Certification: | CE |

| Model Number: | DPP-120 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1unit |

|---|---|

| Price: | USD9800/unit |

| Packaging Details: | Wooden box |

| Delivery Time: | 20-25 work days |

| Payment Terms: | T/T |

| Supply Ability: | 20 units per month |

|

Detail Information |

|||

| Max Shaping Areas And Depth: | 130*70*14mm | Material Quality: | 304 Stainless Steel |

|---|---|---|---|

| Power Supply: | 220V/50Hz 2.4KW | Machine Dimensions: | 1850*650*1200mm |

| Net Weight: | 450kg | ||

| High Light: | 220V 50Hz blister pack sealing machine,Fully Automatic blister pack sealing machine,220V automatic blister sealing machine |

||

Product Description

Butter box blister packaging machine Storage tank with insulation and mixing function

Yellow butter aluminum-plastic blister packaging is a process of packaging yellow butter in plastic or aluminum-plastic composite materials made blister covers in solid or semi-solid state. The advantages of yellow butter aluminum-plastic blister packaging include:

1.Good preservation performance: Yellow butter aluminum-plastic blister packaging can effectively prevent yellow butter from oxidation and pollution, maintain the freshness and taste of the product, and extend the shelf life.

2.Stable quality: Yellow butter aluminum-plastic blister packaging can prevent yellow butter from being affected by the external environment, making the product's quality more stable.

3.Convenient to carry: Yellow butter aluminum-plastic blister packaging can provide lightweight packaging for products, making it easy for users to carry and use.

4.Good environmental performance: Yellow butter aluminum-plastic blister packaging is made of recyclable materials, which is environmentally friendly.

5.Improve product image: Yellow butter aluminum-plastic blister packaging can provide a beautiful appearance design for products, improving product image and brand value.

Technical Specifications:

| Model | DPP-120 |

| Cutting frequency | 10-30 times/min |

| Capacity | 600-1980 plates/h |

| Max shaping areas and depth | 130*70*14mm |

| Air pressure | 0.4-0.6MPa |

| Power supply | 220V/50Hz 2.4KW |

| Main motor power | 0.75KW |

| PVC hard pieces | (width)140*(thickness)0.25-0.5mm |

| PTP aluminum foil | (width)140*(thickness)0.025-0.05mm |

| Dialysis paper | (width)140*50-100g |

| Mould cooling | tap water or recycling water |

| Machine dimensions | 1840*590*1100mm |

| Net weight | 450kg |

Workflow:

Heating of PVC material→PVC blow molding→Automatic filling→Aluminum foil heat sealing→Finished product punching and cutting

![]()

![]()

![]()

The working principle of a flat aluminum-plastic bubble wrap packaging machine is as follows:

1,The medicine is placed into the packaging material, such as plastic bubbles.

2,The packaging material is conveyed to the heat sealing area.

3,The aluminum foil composite material is unwound from the reel and is covered on the plastic bubble.

4,The aluminum foil and plastic bubble enter the heat sealing area, where they are heated and pressure is applied to seal the two materials together.

5,The finished packaging material is moved out of the heat sealing area and into the cooling area.

6,The packaging material is cooled and fixed together to form a sealed package.

7,The finished packaging material is sent to the next production stage or collection box.

The entire process can be controlled by a computerized automation system to ensure efficient production and stable packaging quality. The flat aluminum-plastic bubble wrap packaging machine is typically used to produce single drug packaging with high production efficiency, but it requires mold replacement for packaging of multiple specifications.

The application scenarios of a flat packaging machine are as follows:

1,Pharmaceutical industry: A flat packaging machine can be used to manufacture drug packaging, such as tablets, capsules, and powders.

2,Food industry: A flat packaging machine can be used to manufacture food packaging, such as chocolate, candy, cookies, coffee, etc.

3,Cosmetics industry: A flat packaging machine can be used to manufacture cosmetic packaging, such as creams, shampoos, perfumes, lipsticks, etc.

4,Other industries: A flat packaging machine can also be used to manufacture packaging for other types of products, such as electronic products, medical equipment, hardware accessories, etc.

The flat packaging machine can be adapted to various packaging specifications, and different molds and packaging materials can be selected according to product needs. It has high production efficiency and stable packaging quality, and is widely used in various industries' production and manufacturing processes.

![]()

![]()

![]()

![]()

![]()